Back in 2013, the USCG in Baltimore, MD, came to Atlantic Shrink Wrapping Inc. (ASI) with a unique idea. They wanted to see if having their ships under cover would save them time and money on repairs. ASI President Dustin Hoover along with business partner Christopher Grimm worked with the USCG and developed a concept design to use scaffolding to build a temporary shrink wrapped structure over a 100 ft long ship pictured below.

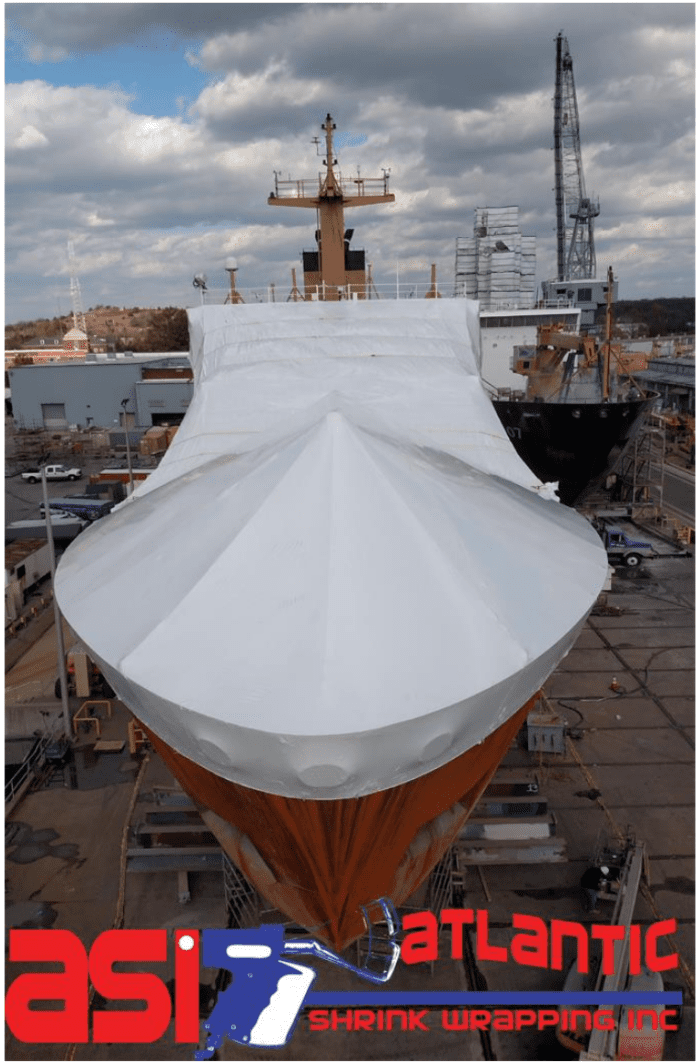

The program was a huge success. Because the smaller 100 ft ships could be craned out of the water next the bulkhead and placed into a cradle, the Coast Guard was able to buy movable oval top structures that they could separate, load a ship inside and close back up. The system is still being used today.

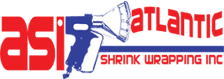

In 2017 the USCG again called on Atlantic Shrink Wrapping Inc. because the tarping programs that they were using to cover portions of their larger ships for water blasting operations were failing. Shrink wrapping the buoy deck on a 235 ft buoy tender was the first project, followed by the bow of the same ship. Atlantic Shrink Wrapping Inc. designed two different containments to cover large open portions of the ship. Everything was so successful with the buoy deck and bow that we were asked to erect a shrink wrap containment around the hull of the ship to allow the painting to be done. The pictures below show those projects.

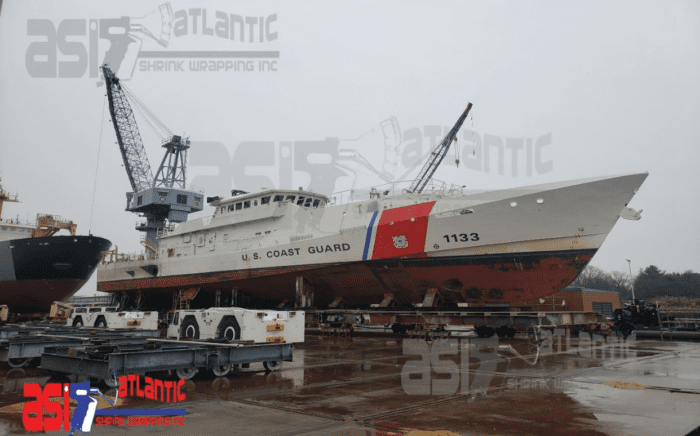

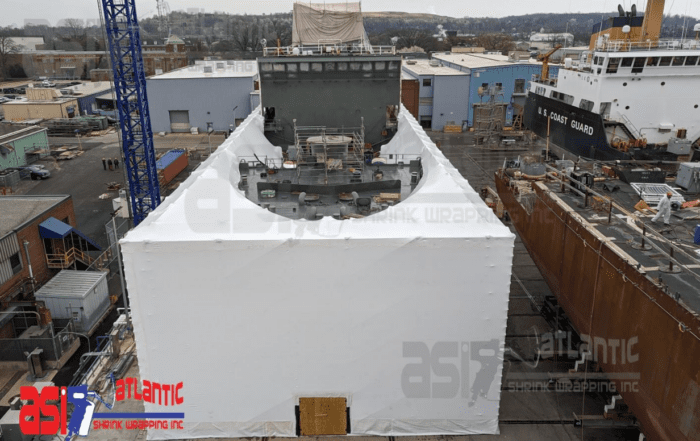

Fast forward to Jan 2020. The USCG had new piers built in the yard to accommodate even more ships and work at one time. Many of which needed to be grit blasted to prepare them for painting. However, the EPA standards that go along with using the new grit materials are strict. The USCG must have a controlled space to use the product and must be able to recycle the product. Total containment and removal of the blasting grit was required. The problem is that the ships are so big that they must be brought out of the water on a cradle, moved into position and then contained.

Atlantic Shrink Wrapping Inc. was first to help the Coast Guard meet these goals with new shrink wrap containment structures.

Atlantic Shrink Wrapping Inc. works closely with a professional scaffolding company in Maryland to build the right structure to accept our shrink wrap. These shrink wrap containments have a full floor, full sized man doors, a full roof and water collection systems.

The below pictures are of the shrink wrap containment structures around and over an 80ft barge, a 150 ft ship and a 235 ft ship.

These shrink wrap containments in Maryland must be able to withstand 60 MPH winds, ice and snow in the winter and cannot leak. If water gets in during the painting process, major time and money will be lost. That is unacceptable. We build our structures with back up systems so that they are very strong and we improve our system every chance we get.

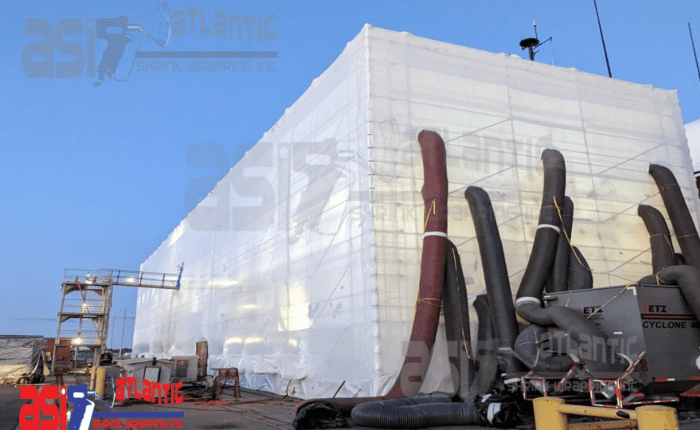

When we are completed with the shrink wrap containment, the USCG goes in and installs vacuum machines to pull the blast git out of the structure during the stripping phase. The way we design and install our material allows the USCG to cut the holes they need in the sides for this purpose.

In the wintertime, they install massive heaters to pump hot air inside the shrink wrap containment. They can get the entire ship to the needed 65 degrees for painting inside our shrink wrap containment.

The picture below shows the massive dust collector hoses in the wall of the shrink wrap containment.

After a three-month blast and paint process, the shrink wrap is removed and recycled, the scaffolding taken down and the ship moved back into the water.

Between 2020 and 2022 we completed several shrink wrap structures at the USCG Yard Curtis Bay , MD.

2023 has been a busy year with two containments completed over 150 ft ships, a containment over an 80 ft barge and a containment around a 235 ft ship and others still in the bidding process.

In the picture below you can see three different shrink wrap structures erected at the same time period in early 2023.

Not only are our shrink wrapping services used by the Coast Guard for containments needed for stripping and painting of vessels but also for work areas to make repairs and or total protection of vessels in the winter.

The pictures below are of a 45 ft patrol boat that needed protection from the weather for needed repairs and six 87ft ships that needed protection during the winter time.

We look forward to the challenges that the Coast Guard will throw at us next. So far, we have met and exceeded their expectations.

Hope you enjoyed this feature of our work for the United States Coast Guard. We are honored every time we are awarded a contract to help our men and women of the United States Military.